When considering which pump manufacturer to choose, there are a few factors to consider. The first is the quality of the products they produce, as well as the customer service they offer.

There are many pump manufacturers out there, and each one has its own style and approach when it comes to manufacturing pumps. Some pump manufacturers prefer to build their pumps from scratch, while others source pumps from other companies and customize them for their own use.

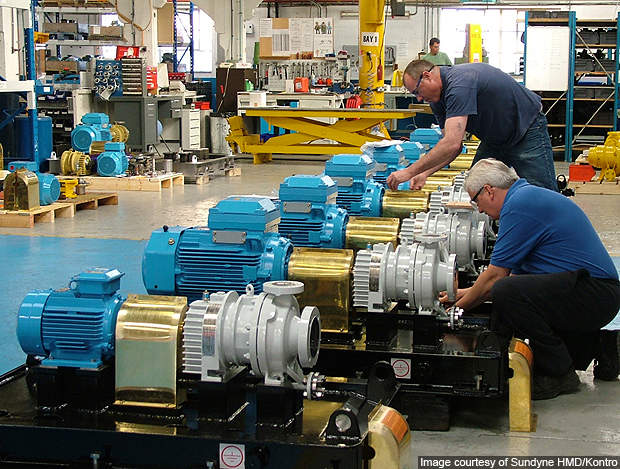

Image Source: Google

Second is the warranty period and whether or not the company has a good reputation. Finally, it's important to find a pump manufacturer that has access to the latest manufacturing technology.

There are different types of pumps available on the market, each with its own set of benefits and drawbacks. To help you make an informed decision, we’ve outlined four of the most common types below.

Piston Pumps: These pumps use pistons to move fluids up and down a cylinder. They’re generally faster and more efficient than rotary or centrifugal pumps, but they tend to be more expensive.

Rotary Pumps: This type uses a moving rotor to create pressurized fluid flow. They’re slower than piston pumps but more affordable, and they can be used in lower-pressure applications.

Centrifugal Pumps: Also known as impellers, these pumps work by using a rotating disk to create a force that pushes fluid through the pump. They’re relatively fast and efficient, but they can be less powerful than other types of pumps and require a larger space for installation.

Piston Pumps vs Rotary Pumps: Rotary pumps are typically slower than piston pumps but are more affordable; they can also be used in lower-pressure applications. Centrifugal pumps are relatively fast and efficient but require a larger space for installation.